上海杰昊传递窗的多样化选择与专业选型指南

上海杰昊传递窗的多样化选择与专业选型指南

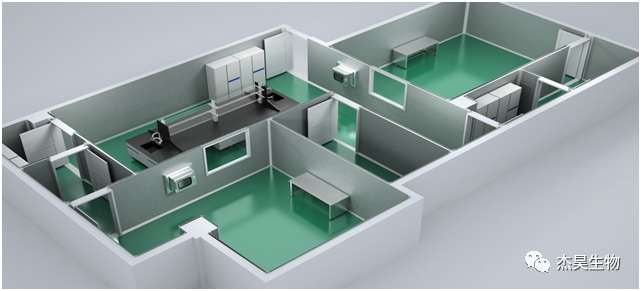

传递窗是安装在房间隔墙上,用于物料传递,具有隔离两侧房间空气的一种箱式装置,其目的是人流、物流区分明确,避免交叉污染,减少开关门次数,设置传递窗是控制污染、节省能源的一种方法。生物安全实验室主要用于对生物危险因子进行分离、培养、检测等实验操作,具备相当的生物危害性,所以生物安全传递窗也是高级生物安全实验室必备的关键防护设备。

传递窗一般以消毒形式的不同来分类,也可以根据运用场所不同来分类。以消毒形式不同分类为:紫外灯灭菌、层流灭菌、脉冲氙光灭菌、过氧化氢灭菌。但从生产厂家来说,更愿意从适用的场所来分类。我们一般分为低级别传递窗和高级别传递窗。

低级别传递窗

L01 紫外灯传递窗

L02 高效传递窗

L03 脉冲氙光消毒传递窗

高级别传递窗

VHP管道式传递窗

H01 生物安全紫外灯传递窗

H02 生物安全高效传递窗

H03 生物安全喷淋传递窗

H04 生物安全渡槽传递窗

VHP传递窗

VHP01 VHP过氧化氢传递窗

L01 紫外灯传递窗

紫外灯传递窗顾名思义是一种采用紫外灯达到灭菌消毒的传递窗。紫外辐射消毒技术是一种传统的物理消毒方式,具有广谱、高效、无二次污染等优点。紫外(UV)根据其波长分为UVA(320~400nm)、UVB(280~320nm)、UVC(200~280NM),其中UVC易被微生物吸收,通过破坏DNA和蛋白质结构起到杀菌的作用。常用的紫外光源主要是254nm的低压汞灯,低压汞灯具有价格低廉、工艺成熟、消毒效果好等优点,但对皮肤和眼睛有伤害。(近期也有研究表明,222nm远紫外线具有杀菌作用,且不会对人的眼睛和皮肤造成伤害。但254nm对远紫外线病毒的灭活效果要好于222nm远紫外线,222nm远紫外线更易被污染物干扰消毒效果。所以目前市场上常规依然选用254nm紫外灯。)

紫外灯的安装方式一般为四面安装,传递窗中间放置置物架,确保全方位杀毒,根据内腔大小设置不同数量的紫外灯。国外更常用紫外灯直接外装的形式,这样照射面更广泛。国内更多是将紫外灯内置,以防止物品碰到撞碎,但照射面会有影响。

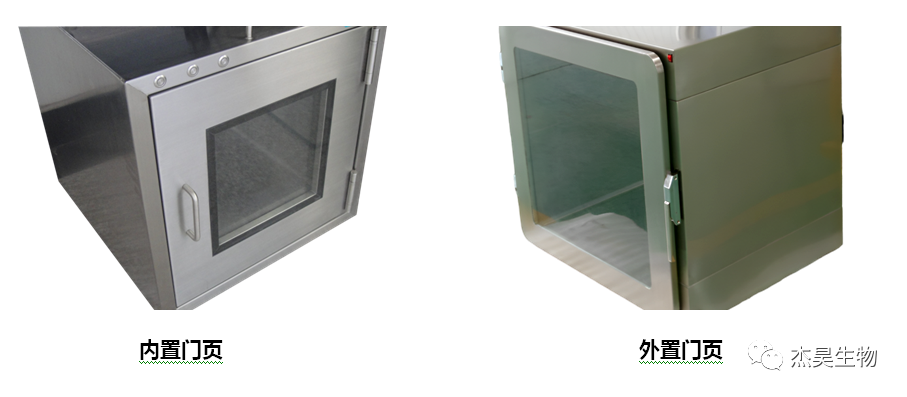

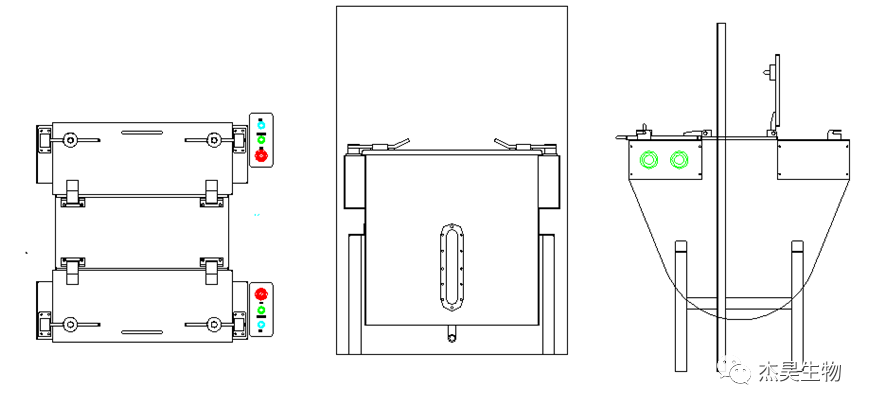

传递窗的门页也有内装和外装二种形式,国内一般用内装方式,确保外面与墙面齐平,外面更容易清洁无死角,但内部有死角。国外更多采用门页外装的形式,这样内腔是圆滑无死角的,内部更易清洁,但因为门页和密封条均外露,易积灰。任何一种形式均有利有弊端,看使用方的取舍。

L02 高效传递窗

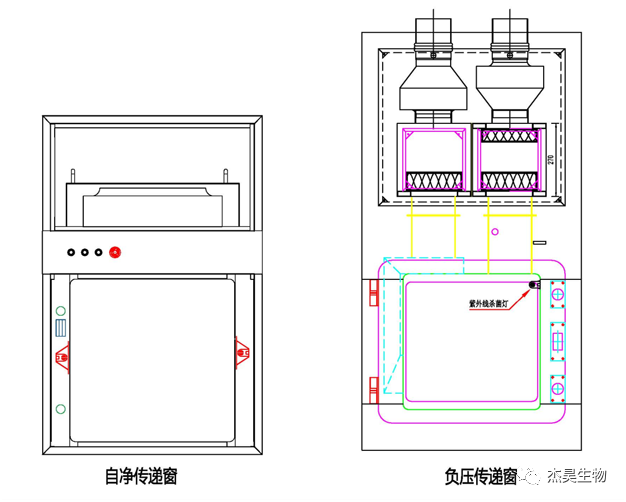

高效传递窗我们一般会分为二类:一是自净型,二是负压型(也叫全进全出型)

高效传递窗我们也叫层流传递窗,设备包含有风机过滤机组和紫外线灯灭菌系统。风机过滤机组是一种自带动力的送风过滤装置,英文全称为(Fan Filter Unit),简称FFU,具有过滤功效的模块化的末端送风装置。风机过滤机组从顶部将空气吸入和并经HEPA过滤,过滤后的洁净空气在整个出风面以0.45m/s±20%左右的速度均匀送出。

自净型:就是空气流动在传递窗内形成内循环,通过初效、高效过滤器进行过滤和紫外灯杀菌达到清洁消毒的目的,设备一般包含初效和高效。

负压型:就是外进风,外送风,通过初效和高效过滤后进入腔内,经紫外灯消毒后,再通过高效排出至管道内,设备一般包含初产和双高效。

L03 脉冲氙光消毒传递窗

脉冲氙光灯应用于传递窗内部作为一种新型的消毒设备,其原理是利用高能脉冲氙光作为消毒光源,产生强烈的脉冲紫外光线进行杀菌。脉冲氙光灯优点是消毒时间短,寿命期内光谱能量几乎不变,工作状态受外界条件变化影响较小,从而减少对传递物品表面消毒时间,适用于洁净度有较高要求的场所快速大量传递物品的物体表面消毒,比传递窗紫外灯更高效。但氙光灯的使用寿命只有数百小时,应定期测试消毒效果并更换。脉冲氙光在高强度照射期间会产生大量臭氧,由于传递窗在对物体消毒期间为密封状态,消毒完毕后由人工打开传递窗门,空气中的臭氧较高,是否对人体黏膜及呼吸系统产生影响,目前尚不明确。

形式同一般的传递窗,只是光源不同。

高级别传递窗

高级别传递窗通常用在P3、P4高等级生物安全实验室中,其与普通传递窗最大的区别就是密封性,即腔内的密封性和设备整体的密封性。验证方法一般是在腔内打入-500Pa的初始压力,采用压力衰减法进行气密性测试,目前检测标准为传递窗腔体内打压后过20min后腔内压力不低于-250Pa的要求。我们工厂的检验标准远高于行业标准,在产品打压环节,一般会在腔内打压1500Pa, 20分钟断气状态下,腔内能达到几乎无泄漏为出厂标准。

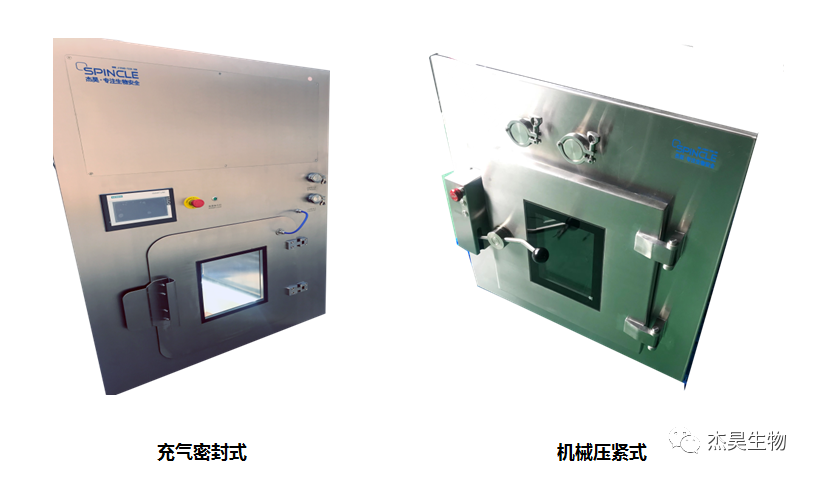

传递窗门页的密封形式我们通常采用二种密封方式:一种为充气式密封(可采用单道或双道),一种为机械压紧式密封。

充气气密结构:设备主体+压缩空气+充气密封条+自控系统

机械压紧结构:设备主体+联杆装置+实心密封条+自控系统

高级别与低级别传递窗在制作工艺上是几乎是完全不同的,一个对密封性没有要求,一个需要达到完全密封,这一点也是完全不同的,当然使用区域也完全不同,但是设备本身的消毒方式基本相同,但是因为高级别传递窗增加了VHP管道或自带VHP发生器,所以每一台都可以进行过氧化氢灭菌。

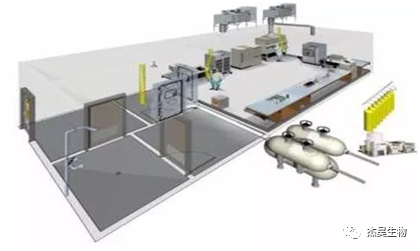

生物安全管道式系列传递窗除了满足生物安全传递窗灭菌的要求外,均可单独外接VHP发生器进行传递窗腔内灭菌,也可以将需要过氧化氢灭菌的物品放入传递窗内,进行过氧化氢灭菌。因为自带VHP发生器功能的传递窗造价相对较高,而且使用位置是固定的,所以客户更多会选择外接灭菌机的VHP管道式传递窗,用户可以将过氧化氢消毒机推到任何一台VHP管道式传递窗使用,节约成本的同时,使用也相对灵活。

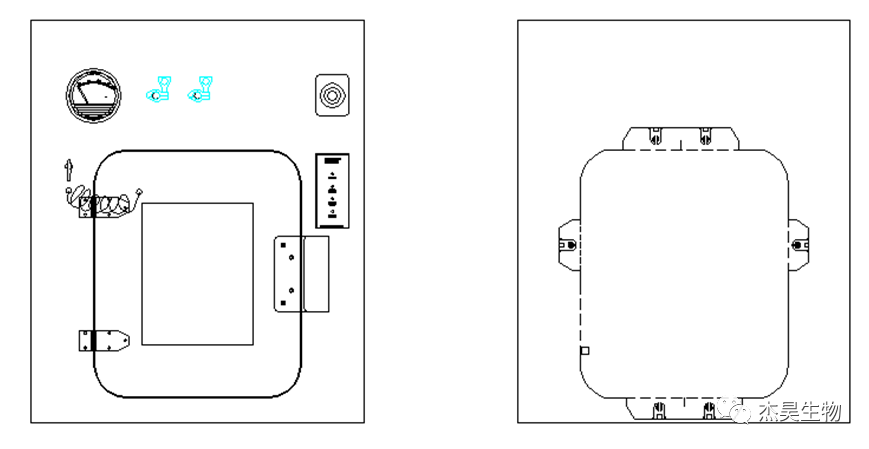

H01 生物安全紫外灯传递窗

生物安全紫外灯传递窗包括箱体+紫外灯灭菌系统+可编程PLC控制系统。

材料可选用不锈钢SUS304或316,设备可与彩钢板墙连接,也可与混凝土墙连接。紫外线灯可根据腔体的大小及灭菌时间的要求来设置数量。一般内部安装有置物架,确保物品的全方位杀菌。

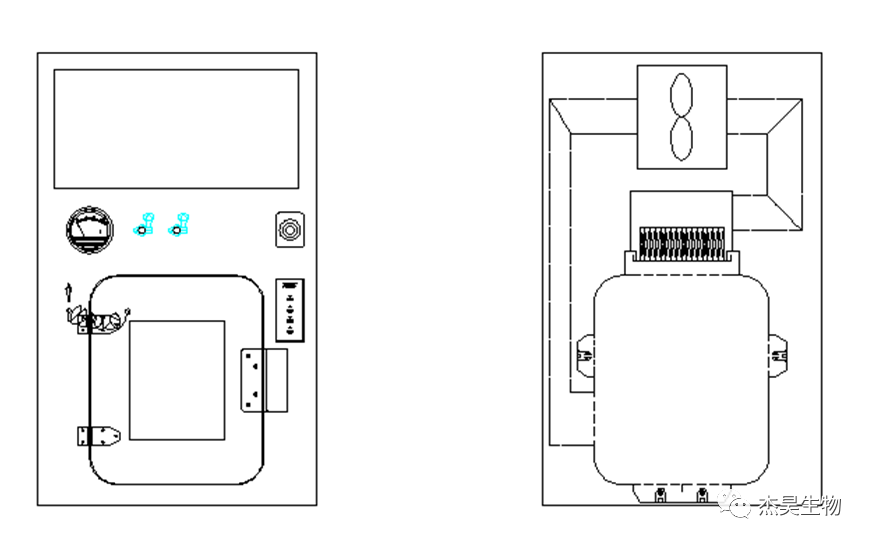

H02 生物安全高效传递窗

生物安全高效传递窗包括箱体+紫外灯灭菌系统+高效自净系统+可编程PLC控制系统。

材料可选用不锈钢SUS304或316,设备可与彩钢板墙连接,也可与混凝土墙连接。紫外线灯可根据腔体的大小及灭菌时间的要求来设置数量,顶部不可安装,会影响出风。

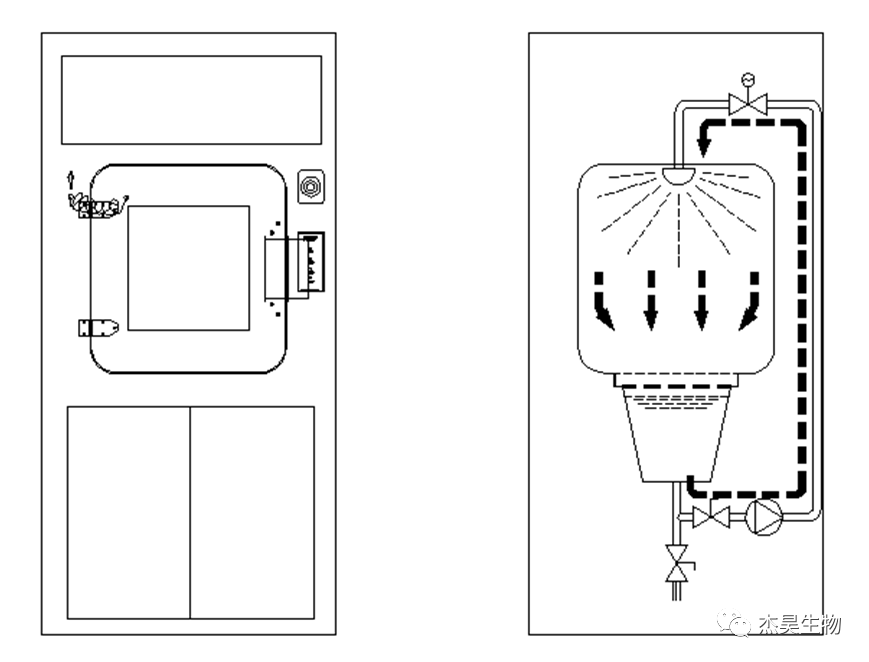

H03 生物安全喷淋传递窗

生物安全喷淋传递窗包括箱体+喷淋系统+可编程PLC控制系统。

材料可选用不锈钢SUS304或316,设备可与彩钢板墙连接,也可与混凝土墙连接。设备采用循环喷淋系统,在设备内倒入消毒液,盖上盖板,将需要消毒的物品放入腔内,启动设备,即可对物品进行全方位喷淋式消毒。

H04 生物安全渡槽传递窗

传递窗的结构根据客户需求其实是多种多样的,包括双腔,多腔,滑动门页等等,操作面板也分按钮式,面贴式,触控式等;控制也会不同,可实现单向型,双向型,多向型。虽然传递窗一般都会选用双门的,但也有三门,四门,可以通向不同的房间。所以传递窗其实是一种完全定制化的产品。

传递窗目前还没有相关的国家标准,所参照的行业标准也是10多年前了,以上仅为上海杰昊公司参与多个国内外项目后对传递窗的理解,如有错误的地方,也欢迎指正,一起为制药行业和生物安全实验室的发展贡献企业的社会价值。